Storing Hydrogen safely

Interview with

Chris - We're joined by Professor Stephen Bennington. He's from ISIS at the Rutherford Appleton Laboratory and his work looks at how nano structures could give us a safe and accessible way to store hydrogen. Steven, hello.

Stephen - Hello. Nice to be here.

Chris - Thank you for joining us on the Naked Scientists. Many people may wonder, because of all the hype about hydrogen, why is it such a wonderful fuel?

Stephen - Well it contains an enormous amount of energy and also, when you burn it of course, it just goes back to water, H2O. So it's a very clean fuel. In fact, it's an ideal fuel if we can find some way of getting it into a car and using it.

Chris - Although that assumes of course that you can make the hydrogen cleanly in the first place.

Stephen - True. Exactly. It's only a store. It's not a fuel. You don't take it out of the ground or anything like that so you have to find some method for making the stuff. But of course, we know how to make clean electricity. We haven't done it properly yet, but you know, you can have wind power, you can have solar, and you can have all these wave machines, and you can have nuclear. And that you can use to make clean hydrogen which is then transferred to a different sector and burn it in your cars.

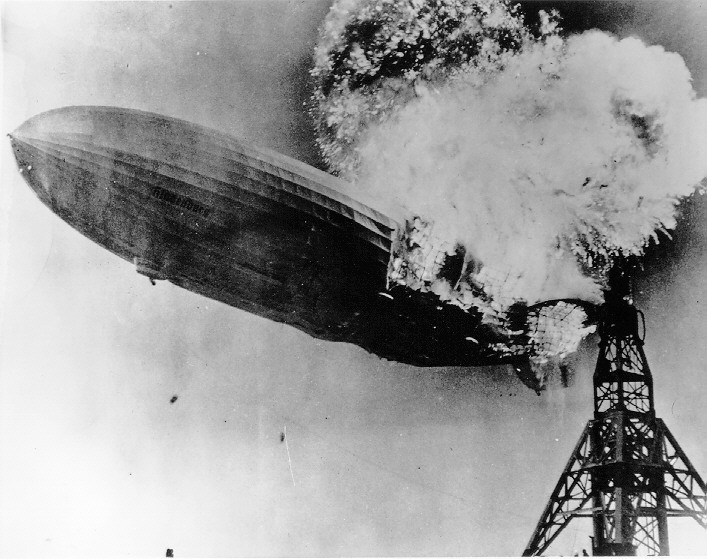

Chris - Well the emphasis really is on the word 'burn' isn't it? Because as the Hindenburg showed us, there are one or two problems with using this wonder fuel as well.

Stephen - Well, in principle, it's not actually as dangerous as petrol. They've done these tests and if you puncture your fuel tank in your car, the petrol flows underneath the car, sets alight, and then burns up through the car, and you're a toast. But hydrogen of course burns upwards and so generally, it burns away from you. So if you look at the Hindenburg, actually, most of the people survived. You wouldn't have that in a plane crash. In a plane crash, you'd be dead. So it's not as bad as people think. It may have a bad image and it is dangerous. Anything that can propel you along a motor way at 70 miles an hour, it's going to have a lot of energy in it, so you know, it's not going to be perfectly safe, but it's safer than petrol probably.

Chris - So why are people worried about hydrogen and why don't we just make cars with a big hydrogen cylinder in the back, and people go to the garage and fill that with hydrogen. If it's safer than fuel, it shouldn't be a problem.

Stephen - It's not the fact that it's the fuel itself, but if you want to get enough hydrogen to fuel your car, you need to pressurise it, and typically, the sort of tests that Toyota and other people have done so they can drive their car 700 kilometres require tanks which have 700 bars of hydrogen, 700 atmospheres. I mean, that's a huge pressure and you can imagine...

Chris - You have a big tank, I presume.

Stephen - It's a fairly big tank, but you know, that's not really the problem. It's 700 bars and you can have 700 bars of air in the back of your car, and that's not going to be safe. You're going to have insurance problems, you're going to have licensing problems. It's not going to be a thing that a consumer is easily going to want to buy.

Chris - So there's a transportation and a safety issue.

Stephen - Absolutely.

Chris - What are the solutions?

Stephen - Well what we're looking at or a huge number of people around the world are looking at, is a way to store it within a solid material. And if you can store in a solid material at ambient pressures and temperature, you just heat it up slightly and hopefully at low-ish temperatures then the hydrogen is released and you can use it. And you can store concentrations in many materials that are more than in these high pressure tanks, but they're not ideal for many reasons.

Chris - I get it. So you can make a material that enables you to store more hydrogen than you would get in a tank at those tremendous pressures, but at lower pressure.

Stephen - Yes.

Chris - And therefore it's much safer.

Stephen - Absolutely.

Chris - How on earth does that work?

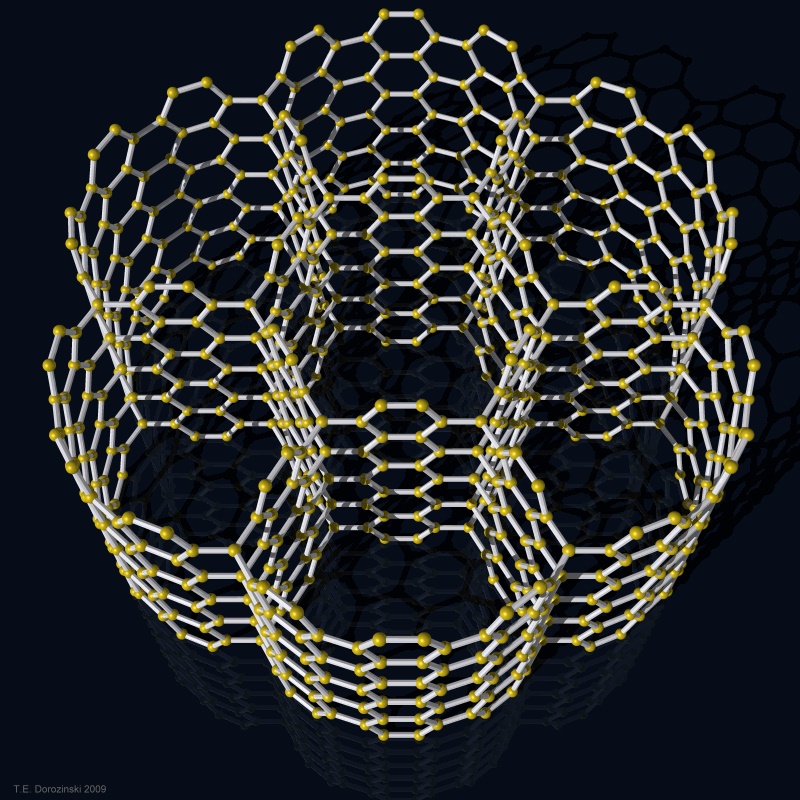

Stephen - Well, it sits in the interstices of the atoms. Well there are various different methods all right. So, one method is you take a very high surface area material and you know, carbon nano tubes were mooted a few years ago, and the hydrogen then sticks on the outside of that. And the other method is when we take one where the material soaks it up like a sponge, and it sits in between the atoms of the material, so one of those two.

Chris - And your approach?

Stephen - Well we do both. You know, kind of hedging our bets that one of them is going to work. The problem is that the material, the high surface area material is you have to cool the material down, so it's cryogenic which is not perfect. You'd rather not have that in your car. And the other ones, all the ones where it goes into the interstices of a normal material, they run up to a higher temperature. And so, we're looking at ways - nano technology is one of them - of bringing them down so they operate ambient pressures and ambient temperatures.

Chris - So, for want of a better expression, you want to build some kind of molecular cage which enables you to put the hydrogen into that cage which will soak it up safely at low pressure, and enable you to store large amounts. Is this deliverable? Can we do this?

Stephen - Well yes, we think so. We've got prototypes of things that are kind of working. Nano technology is really the answer and that's what we are concentrating at the moment. So we're taking these materials that normally run, let's say, 200 or 300 degrees centigrade and we're making them very small so making them into a nano scale material. And if you do that - well I'm really sort of going of ourselves here, but one of the things, it reduces the temperature which it operates.

But there's also another problem with many of these materials. In fact all of these materials run at these high temperatures. They take an extraordinarily long time for the hydrogen to come out, and you can't wait half an hour when you put your foot in the accelerator to get off. You got to have it now. And if you make the materials small, then of course, you reduce all the - what they called the 'rate limiting' steps for the hydrogen to get out. You know, so it's got a large surface area, so the hydrogen can get to the surface, recombine, and get away and diffuse away. When it's inside the material itself, it doesn't have very far to diffuse, but the key point here is that it transforms in a different way. The phase transformation from the hydride to the non-hydride phase is completely different. So in a normal bulk material, you have a big lump of it, the outer surface, like an onion skin around the outside might go to the hydride phase, and then it would massively expand, and you'd have this big phase boundary between hydride phase and the non-hydride phase.

Chris - This is meaning where the atoms of hydrogen stuck on as the hydride form.

Stephen - Yes, that's right. So you've transformed the material from one form to another. It has a big volume change and driving that phase boundary through your material is hugely energetic. It takes a lot of energy and it really disrupts...

Chris - Oh, I see - by shrinking it it's much easier because you're doing this on the small scale throughout rather than trying to get big blobs.

Stephen - Kind of. I mean, there are two things. One is that if you have a big lump of material, that skin around the outside can stop the hydrogen getting into the centre, but also, on a nano scale material, it just switches right back, it clicks from one phase to the other and it doesn't have any phase boundary at all. It just switches and that's going to be very, very quick. It can go in seconds. And so that's why it reduces the temperature at which it operates and it can make the hydrogen come out really fast, and that's been proven.

Chris - And just to finish off, can you tell us what is the material, the magic material that's doing this and how are you building it?

Stephen - There are a large number of materials, but the technique we're using is called 'electro spinning." Actually not too different to what we heard in the previous article, but if you extrude a small amount of a hydride material surrounded by a polymer out of a needle and then put a large electric field on it, it pulls a very, very fine fibre, a nano structured fibre, and it makes a kind of tissue-like material, and that material works. I mean you know, you can use various different hydrides in the centre, and we're trying all sorts of different ones, and you get the reduction of the temperature and you also get this high speed hydrogen release.

Chris - And just to finish, how long before we see this actually being commercially viable rather than something in a laboratory?

Stephen - Well we're setting up a company now and hopefully in 5 year's time, we'll have a product. So, that's the plan. You know, things can slip up, but that's what we're aiming for.

Chris - So this is soon. I mean, that's fantastic news, isn't it? To think that you're actually going now commercially for this.

Stephen - That's right, but we're talking about prototypes in that time. So you know, in the same way that you can buy these prototype electric battery vehicles, lithium battery vehicles, in 5 year's time, hopefully, these will be available on trial.

Chris - Terrific. Thank you. Stephen Bennington from the STFC's ISIS Neutron Source.

Comments

Add a comment